Inconel Fasteners

Table of Content

EN Nicr15Fe industrial Fastener, BS Na 13 high tensile Fastener, Afnor Nc15Fe11M industrial Fastener, Inconel 600 high tensile Fastener, Gost Xh60Bt industrial Fastener, ASTM B166 high tensile Fastener, JIS Ncf 601 industrial Fastener, UNS N06625 industrial Fastener, UNS N06625 high tensile Fastener, Gost Хн75Мбтю high tensile Fastener, JIS Ncf 625 industrial Fastener, JIS Ncf 718 high tensile Fastener, ASME SB637 high tensile Fastener,.

Ranflex Metals are the leading manufacturer of high integrity inconel fasteners (e.g. bolts, set screws, stud-bolts, nuts and washers), meeting clients’ exacting demands for critical applications in hostile environments. Whether for offshore (buoyancy and petrochemical), seawater, pump, valve or nuclear, the demands for an exceptional service and supply is never ending. We believe manufacturing bolting in exotic materials is an art form and it is something we have perfected at Ranflex Metals.

ASME SA166 Hot Forged Fastener stockiest, BS Na 13 Hot Forged Fastener price per kg, ASME SB166 industrial Fastener stockyards, 2.4851 Hot Forged Fastener manufacturer, JIS Ncf 625 industrial Fastener distributor, ASME SB446 Hot Forged Fastener price list, Werkstoff Nr. 2.4856 Hot Forged Fastener weight calculator, ASME SB637 industrial Fastener manufacturer, JIS Ncf 718 Hot Forged Fastener stockiest, ASME SB637 industrial Fastener price list in India,.

Our Inconel Alloy Fasteners product range includes Inconel Bolts, Hexagon head bolt, Hexagon head screw, Round head square neck bolt, Hexagon socket head cap screw in full thread and half thread, Hexagon wood screw, Hexagon socket button head screw, Hexagon socket button flange screw, Hexagon socket counter sunk head cap screw in full thread and half thread, square nuts, square weld nuts, hexagon weld nuts, thick nyloc nuts, hexagon flange nuts, threaded rods, dowel screws, Plain / Flat Washer, Spring Washers, Countersunk Washer,Tooth Lock Washer and many more. We provide products as per DIN, ANSI, JIS standards.

Inconel® fasteners, like Inconel 600, 601, 625, 686, 718 & 725 fasteners, are a family of nickel-chromium-molybdenum alloys used for their high strength at elevated temperatures and good corrosion resistance. Because of its high thermal stability, Inconel can be used in service temperatures ranging from cryogenic to 2200°F (982°C).If we do not have your Inconel Fasteners in stock (Inch or Metric) we can have these manufactured to your specification. Inconel Alloy Fasteners Manufacturers & Suppliers In India

Common Grades of Inconel Fasteners :

Inconel 600 Fasteners

A nickel-chromium alloy with good carburization and oxidation resistance through 2000°F. The alloy has long been used in the heat treating industry and Inconel 600 has useful resistance to dry Cl2 and HCl gases at moderately elevated temperatures.

Inconel 601 Fasteners

Inconel 601 is highly resistant to oxidation through 2200°F even under severe thermal cycling. The alloy has good high temperature strength, and retains its ductility after long service exposure. Inconel 601 alloy has good hot corrosion resistance under oxidizing conditions.

Inconel 625 Fasteners

Inconel 625 is the workhorse of the Inconel family and is one of the most common grades for fasteners. It exhibits high creep-rupture strength and is oxidation resistant to 1800°F (982°C). Inconel 625 has excellent resistance to hot seawater, scrubber environments and reducing acids and this alloy resists a wide range of severely corrosive environments and is especially resistant to pitting and crevice corrosion

Inconel 686 Fasteners

An alloy designed for outstanding corrosion resistance in a wide range of severe environments. The alloy is used in the most severe environments encountered in chemical processing, pollution control, pulp and paper production, and treatment of industrial and municipal waste.

Inconel 718 Fasteners

Inconel 718 is the most common grade of the hardenable Inconels. This precipitation-hardened nickel-chromium alloy combines outstanding corrosion resistance and high strength at elevated temperatures. The alloy is a about 2x as strong as Inconel 625 having excellent creep-rupture strength at temperatures to 1300°F (700°C) and usable up to 1800°F (982°C). Inconel 718 is often used in gas turbines, rocket motors, spacecraft, nuclear reactors, pumps, and tooling.

Inconel 725 Fasteners

A nickel-chromium-molybdenum-niobium age-hardenable alloy that has essentially the same corrosion resistance as Inconel 625, but with a strength of that is twice that of annealed Inconel 625. The strength of this alloy is developed by heat treatment to achieve high ductility and toughness. The alloy is resistant to hydrogen embrittlement and stress-corrosion cracking as well.

Afnor Nc15Fe11M Hot Forged Fastener, No 2.4816 Hot Forged Fastener, 2.4851 Hot Forged Fastener, ASTM B166 industrial Fastener, ASME SB166 industrial Fastener, ASME SB446 high tensile Fastener, Werkstoff Nr. 2.4856 industrial Fastener, Gost Хн75Мбтю Hot Forged Fastener, JIS Ncf 718 industrial Fastener, ASTM B637 industrial Fastener, UNS N07718 industrial Fastener,.

Specification of Inconel Fasteners :

| Specifications | ASTM B166 ASME SB166 |

| Standard | , ISO ,JIS ,GB, IS, BS, ASTM |

| Size | M0.2 to M33 | 3/6" to 2" | Custom Sizes |

| Length | 3 mm to 200 mm | Custom Sizes |

| Dimensions | 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3 |

| Form | Hex, Threading, Square, Round as per Gauge Etc. |

| Threads | Unless otherwise specified, the threads shall be rolled or cut and tapped horizontally or vertically |

| Threads available | UNF, BSW, BSF, METRIC, UNC, or as required |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Test Certificate | As per EN 10204 / 3.1 Manufacturer Test Certificate, PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified |

| Raw materials Source | JSPL, Mukund Steel, Tata Steel, Dhamm Steel, Usha Martin,etc. |

| Packing | IN BULK: canton, pallet, Small Boxs / carton / pallet, or customer request |

| Surface Coating |

Cadmium Coating Hot Dipped Galvanizing Coating Ptfe Coated Inconel Fasteners Phosphate Coating Teflon Coating Xylon Coating Zinc Coating |

Equivalent s of Inconel Steel Fasteners :

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Incoloy 600 | 2.4816 | N06600 | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | NC15FE11M | NiCr15Fe |

| Incoloy 625 | 2.4856 | N06625 | NCF 625 | NA 21 | ХН75МБТЮ | NC22DNB4M | NiCr22Mo9Nb |

| Incoloy 718 | 2.4668 | N07718 | NCF 718 | – | – | – | – |

Chemical Composition of Inconel Steel Fasteners :

| Inconel | Ni | Cr | Fe | Mo | Nb | Co | Mn | Cu | Al | Ti | Si | C | S | P | B |

| 600 | 72.0 | 14.0-17.0 | 6.0-10.0 | 1.0 | 0.5 | 0.5 | 0.15 | 0.015 | |||||||

| 625 | 58.0 | 20.0-23.0 | 5.0 | 8.0-10.0 | 3.15-4.15 | 1.0 | 0.5 | 0.4 | 0.4 | 0.5 | 0.1 | 0.015 | 0.015 | ||

| 718 | 50.0-55.0 | 17.0-21.0 | balance | 2.8-3.3 | 4.75-5.5 | 1.0 | 0.35 | 0.2-0.8 | 0.65-1.15 | 0.3 | 0.35 | 0.08 | 0.015 | 0.015 | 0.006 |

Mechanical Properties of Inconel Steel Fasteners :

| Inconel 600 | Inconel 601 | Inconel 625 | |

| Density | 8.47 g/cm3 | 8.1 g/cm3 | 8.4 g/cm3 |

| Melting Point | 1413 °C (2580 °F) | 1411 °C (2571 °F) | 1350 °C (2460 °F) |

| Tensile Strength | Psi – 95,000 , MPa – 655 | Psi – 80,000 , MPa – 550 | Psi – 1,35,000 , MPa – 930 |

| Yield Strength (0.2%Offset) | Psi – 45,000 , MPa – 310 | Psi – 30,000 , MPa – 205 | Psi – 75,000 , MPa – 517 |

| Elongation | 40 % | 30 % | 42.5 % |

Inconel 600 industrial Fastener price per kg, Gost Мнжмц 28-2,5-1,5 high tensile Fastener distributor, EN Nicr15Fe high tensile Fastener wholesaler, UNS N06601 Hot Forged Fastener trader, Grade Inconel 601 Hot Forged Fastener weight calculator, BS Na 49 industrial Fastener price list in India, BS Na 21 Hot Forged Fastener catalogue, EN Nicr22Mo9Nb Hot Forged Fastener dealer, Werkstoff Nr. 2.4856 Hot Forged Fastener wholesaler, BS Na 21 industrial Fastener manufacturer, JIS Ncf 718 Hot Forged Fastener At Factory Price, ASME SB637 Hot Forged Fastener manufacturer, Inconel 718 Hot Forged Fastener distributor, ASME SB637 high tensile Fastener weight calculator,.

Modern Equipments

Expert Engineers

Efficient Factories

Well Maintained

Property Class of Inconel Steel Fasteners :

Ranflex Metals is majorly known as a Stainless Steel Fasteners manufacturer in the global market. Wherein Inconel Steel Fasteners are extensively supplied from us in SS Special fasteners segment. The Inconel Steel Fasteners density kg m3 is around 8000 Kg/m3 which gives a great aspect to various listed down steel fasteners :

For Bolts & Screws: A2-70, A2-80, A4-70, A4-80, F593C, F593D, F593G, F593H

For Nuts: A2-70, A2-80, A4-70, A4-80, F594C, F594D, F594G, F594H, A2-035, A4-040

For SHCS: F837B, F837C, F837E, F837

For Threaded Rods: A2-70, A2-80, A4-70, A4-80, F593C, F593D, F593G, F593H, B8, B8M CL1 & CL2

Dimensions of Inconel Steel Fasteners :

Inconel Steel Bolts Dimensions Chart :

| Nominal Size Of D | Diameter Of Body | ASTM B166 Head Thickness | ASTM B166 Flats Acro | ASTM B166 Corners Acro | ||||

|---|---|---|---|---|---|---|---|---|

| D (MAXIMUM) | D (MINIMUM) | H (MAXIMUM) | H (MINIMUM) | F (MAXIMUM) | F (MINIMUM) | C (MAXIMUM) | C (MINIMUM) | |

| m10 | 10.00 | 9.78 | 6.63 | 6.17 | 17.00 | 15.73 | 18.48 | 17.77 |

| m12 | 12.00 | 11.73 | 7.76 | 4.24 | 19.00 | 17.73 | 20.78 | 20.03 |

| m14 | 14.00 | 13.73 | 9.09 | 8.51 | 22.00 | 20.67 | 24.25 | 23.35 |

| m16 | 16.00 | 15.73 | 10.32 | 9.68 | 24.00 | 23.67 | 27.71 | 26.75 |

| m20 | 20.00 | 19.67 | 12.88 | 12.12 | 30.00 | 29.16 | 34.64 | 32.95 |

| m24 | 24.00 | 23.67 | 15.44 | 14.56 | 36.00 | 35.00 | 41.57 | 39.55 |

| m30 | 30.00 | 29.67 | 19.48 | 17.92 | 46.00 | 45.00 | 53.12 | 50.85 |

| m36 | 36.00 | 35.61 | 23.38 | 21.63 | 55.00 | 53.80 | 63.51 | 60.79 |

| m42 | 42.00 | 41.38 | 26.97 | 25.03 | 65.00 | 62.90 | 75.06 | 71.71 |

| m48 | 48.00 | 47.38 | 31.07 | 28.93 | 75.00 | 72.60 | 86.60 | 82.76 |

| m56 | 56.00 | 55.26 | 36.2 | 33.80 | 85.00 | 82.20 | 98.15 | 93.71 |

| m64 | 64.00 | 63.26 | 41.32 | 38.68 | 95.00 | 91.80 | 109.70 | 104.65 |

| m72 | 72.00 | 71.26 | 46.45 | 43.55 | 105.00 | 101.40 | 121.24 | 115.60 |

| m80 | 80.00 | 79.26 | 51.58 | 48.42 | 115.00 | 111.00 | 132.72 | 126.54 |

| m90 | 90.00 | 89.13 | 57.74 | 54.26 | 130.00 | 125.50 | 150.11 | 143.07 |

| m100 | 90.00 | 99.13 | 63.9 | 60.10 | 145.00 | 140.00 | 167.43 | 159.60 |

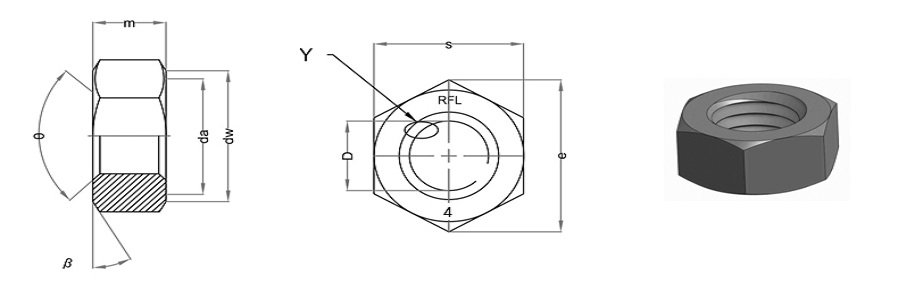

Inconel Steel Hex Nuts Dimensions Chart :

| Nominal Size Of Thread Diameter | F | G | H | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Across Flats Width |

Across Corners Width |

Thickness Row | |||||||

| Basic | Maximum | Minimum | Maximum | Minimum | Basic | Maximum | Minimum | ||

| 1/4 | .2500 | 7/16 | .438 | .428 | .505 | .488 | 7/32 | .226 | .212 |

| 5/16 | .3125 | 1/2 | .500 | .489 | .577 | .557 | 17/64 | .273 | .258 |

| 3/8 | .3750 | 9/16 | .562 | .551 | .650 | .628 | 21/64 | .337 | .479 |

| 7/16 | .4375 | 11/16 | .688 | .675 | .794 | .768 | 3/8 | .385 | .365 |

| 1/2 | .5000 | 3/4 | .750 | .736 | .866 | .840 | 7/16 | .448 | .427 |

| 9/16 | .5625 | 7/8 | .875 | .861 | 1.010 | .982 | 31/64 | .496 | .473 |

| 5/8 | .6250 | 15/16 | .938 | .922 | 1.083 | 1.051 | 35/64 | .559 | .535 |

| 3/4 | .7500 | 1-1/8 | 1.125 | 1.088 | 1.299 | 1.240 | 41/64 | .665 | .617 |

| 7/8 | .8750 | 1-5/16 | 1.312 | 1.269 | 1.516 | 1.447 | 3/4 | .776 | .724 |

| 1 | 1.0000 | 1-1/2 | 1.500 | 1.450 | 1.732 | 1.653 | 55/64 | .887 | .831 |

| 1-1/8 | 1.1250 | 1-11/16 | 1.688 | 1.631 | 1.949 | 1.859 | 31/32 | .999 | .939 |

| 1-3/8 | 1.3750 | 2-1/16 | 2.062 | 1.994 | 2.382 | 2.273 | 1-11/64 | 1.206 | 1.138 |

| 1-1/2 | 1.500 | 2-1/4 | 2.250 | 2.175 | 2.598 | 2.480 | 1-9/32 | 1.ASTM A194 GR. 8 | 1.245 |

| 1-5/8 | 1.6250 | 2-7/16 | 2.438 | 2.356 | 2.815 | 2.686 | 1-25/64 | 1.429 | 1.353 |

| 1-3/4 | 1.7500 | 2-5/8 | 2.625 | 2.538 | 3.031 | 2.893 | 1-1/2 | 1.540 | 1.460 |

| 2 | 2.0000 | 3 | 3.000 | 2.900 | 3.464 | 3.306 | 1-23/32 | 1.763 | 1.675 |

| 2-1/4 | 2.2500 | 3-3/8 | 3.375 | 3.263 | 3.897 | 3.719 | 1-15/16 | 1.986 | 1.890 |

| 2-1/2 | 2.5000 | 3-3/4 | 3.750 | 3.625 | 4.330 | 4.133 | 2-5/32 | 2.209 | 2.105 |

| 2-3/4 | 2.7500 | 4-1/8 | 4.125 | 3.988 | 4.763 | 4.546 | 2-3/8 | 2.431 | 2.319 |

Inconel Steel Stud Bolts Dimensions Chart :

| Diameter | ||

|---|---|---|

| Plain | ||

| UNC | 8UN | |

| 1/2 | 19568 | - |

| 5/8 | 19569 | - |

| 3/4 | 19570 | |

| 7/8 | 19571 | - |

| 1 | 19572 | - |

| 11/8 | 19573 | 13979 |

| 11/4 | 19574 | 13980 |

| 13/8 | 19656 | 13981 |

| 11/2 | 19657 | 13982 |

| 13/4 | 19658 | 13983 |

| 2 | 19659 | 13984 |

| Available lengths 12 Inch ASME B18.31.3, Also available lengths Dimensions 6 Inch |

||

Inconel Steel Square Bolts Dimensions Chart :

| Size Of Bolt | A (maximum) | B | C (minimum) | D | E | F Length Of Thread for Bolt Length |

||

|---|---|---|---|---|---|---|---|---|

| maximum | minimum | 6 Inch and shorter |

over 6 Inch | |||||

| 1/4" | 0.260 | 3/8 | 0.498 | 11/64 | 0.03 | 0.01 | 0.750 | 1.000 |

| 5/16" | 0.324 | 1/2 | 0.665 | 13/64 | 0.03 | 0.01 | 0.875 | 1.125 |

| 3/8" | 0.388 | 9/16 | 0.747 | 1/4 | 0.03 | 0.01 | 1.000 | 1.250 |

| 7/16" | 0.452 | 5/8 | 0.828 | 19/64 | 0.03 | 0.01 | 1.125 | 1.375 |

| 1/2" | 0.515 | 3/4 | 0.995 | 21/64 | 0.03 | 0.01 | 1.250 | 1.500 |

| 5/8" | 0.642 | 15/16 | 1.244 | 27/64 | 0.06 | 0.02 | 1.500 | 1.750 |

| 3/4" | 0.768 | 1-1/8 | 1.494 | 1/2 | 0.06 | 0.02 | 1.750 | 2.000 |

| 7/8" | 0.895 | 1-5/16 | 1.742 | 19/32 | 0.06 | 0.02 | 2.000 | 2.250 |

| 1" | 1.022 | 1-1/2 | 1.991 | 21/32 | 0.09 | 0.03 | 2.250 | 2.500 |

| 1-1/8" | 1.149 | 1-11/16 | 2.239 | 3/4 | 0.09 | 0.03 | 2.500 | 2.750 |

| 1-1/4" | 1.277 | 1-7/8 | 2.489 | 27/32 | 0.09 | 0.03 | 2.750 | 3.000 |

| 1-3/8" | 1.404 | 2-1/16 | 2.738 | 29/32 | 0.09 | 0.03 | 3.000 | 3.250 |

| 1-1/2" | 1.531 | 2-1/4 | 2.986 | 1 | 0.09 | 0.03 | 3.250 | 3.500 |

Inconel Steel Heavy Hex Bolts Dimensions Chart :

| Nominal Size Of D | Diameter Of Body | Thickness Of Head | Flats Across | Bolts Corners Across | ||||

|---|---|---|---|---|---|---|---|---|

| D (Maximum) | D (Minimum) | H (Maximum) | H (Minimum) | F (Maximum) | F (Minimum) | C (Maximum) | C (Minimum) | |

| m10 | 10.00 | 9.78 | 6.63 | 6.17 | 17.00 | 15.73 | 18.48 | 17.77 |

| m12 | 12.00 | 11.73 | 7.76 | 4.24 | 19.00 | 17.73 | 20.78 | 20.03 |

| m14 | 14.00 | 13.73 | 9.09 | 8.51 | 22.00 | 20.67 | 24.25 | 23.35 |

| m16 | 16.00 | 15.73 | 10.32 | 9.68 | 24.00 | 23.67 | 27.71 | 26.75 |

| m20 | 20.00 | 19.67 | 12.88 | 12.12 | 30.00 | 29.16 | 34.64 | 32.95 |

| m24 | 24.00 | 23.67 | 15.44 | 14.56 | 36.00 | 35.00 | 41.57 | 39.55 |

| m30 | 30.00 | 29.67 | 19.48 | 17.92 | 46.00 | 45.00 | 53.12 | 50.85 |

| m36 | 36.00 | 35.61 | 23.38 | 21.63 | 55.00 | 53.80 | 63.51 | 60.79 |

| m42 | 42.00 | 41.38 | 26.97 | 25.03 | 65.00 | 62.90 | 75.06 | 71.71 |

| m48 | 48.00 | 47.38 | 31.07 | 28.93 | 75.00 | 72.60 | 86.60 | 82.76 |

| m56 | 56.00 | 55.26 | 36.2 | 33.80 | 85.00 | 82.20 | 98.15 | 93.71 |

| m64 | 64.00 | 63.26 | 41.32 | 38.68 | 95.00 | 91.80 | 109.70 | 104.65 |

| m72 | 72.00 | 71.26 | 46.45 | 43.55 | 105.00 | 101.40 | 121.24 | 115.60 |

| m80 | 80.00 | 79.26 | 51.58 | 48.42 | 115.00 | 111.00 | 132.72 | 126.54 |

| m90 | 90.00 | 89.13 | 57.74 | 54.26 | 130.00 | 125.50 | 150.11 | 143.07 |

| m100 | 90.00 | 99.13 | 63.9 | 60.10 | 145.00 | 140.00 | 167.43 | 159.60 |

Inconel Steel Heavy Hex Nuts Dimensions :

| Nominal Size For Thread Diameter | F | G | H | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Width Of Across Flats | Width Of Across Corners | Thickness Table | |||||||

| Basic | Maximum | Minimum | Maximum | Minimum | Basic | Maximum | Minimum | ||

| 1/4 | .2500 | 7/16 | .438 | .428 | .505 | .488 | 7/32 | 226 | .212 |

| 5/16 | .3125 | 1/2 | .500 | .489 | .577 | .557 | 17/64 | .273 | .258 |

| 3/8 | .3750 | 9/16 | .562 | .551 | .650 | .628 | 21/64 | .337 | .479 |

| 7/16 | .4375 | 11/16 | .688 | .675 | .794 | .768 | 3/8 | .385 | .365 |

| 1/2 | .5000 | 3/4 | .750 | .736 | .866 | .840 | 7/16 | .448 | .427 |

| 9/16 | .5625 | 7/8 | .875 | .861 | 1.010 | .982 | 31/64 | .496 | .473 |

| 5/8 | .6250 | 15/16 | .938 | .922 | 1.083 | 1.051 | 35/64 | .559 | .535 |

| 3/4 | .7500 | 1-1/8 | 1.125 | 1.088 | 1.299 | 1.240 | 41/64 | .665 | .617 |

| 7/8 | .8750 | 1-5/16 | 1.312 | 1.269 | 1.516 | 1.447 | 3/4 | .776 | .724 |

| 1 | 1.0000 | 1-1/2 | 1.500 | 1.450 | 1.732 | 1.653 | 55/64 | .887 | .831 |

| 1-1/8 | 1.1250 | 1-11/16 | 1.688 | 1.631 | 1.949 | 1.859 | 31/32 | .999 | .939 |

| 1-3/8 | 1.3750 | 2-1/16 | 2.062 | 1.994 | 2.382 | 2.273 | 1-11/64 | 1.206 | 1.138 |

| 1-1/2 | 1.500 | 2-1/4 | 2.250 | 2.175 | 2.598 | 2.480 | 1-9/32 | 1.ASTM A194 GR. 8 | 1.245 |

| 1-5/8 | 1.6250 | 2-7/16 | 2.438 | 2. | 2.815 | 2.686 | 1-25/64 | 1.429 | 1.353 |

| 1-3/4 | 1.7500 | 2-5/8 | 2.625 | 2.538 | 3.031 | 2.893 | 1-1/2 | 1.540 | 1.460 |

| 2 | 2.0000 | 3 | 3.000 | 2.900 | 3.464 | 3.306 | 1-23/32 | 1.763 | 1.675 |

| 2-1/4 | 2.2500 | 3-3/8 | 3.375 | 3.263 | 3.897 | 3.719 | 1-15/16 | 1.986 | 1.890 |

| 2-1/2 | 2.5000 | 3-3/4 | 3.750 | 3.625 | 4.330 | 4.133 | 2-5/32 | 2.209 | 2.105 |

| 2-3/4 | 2.7500 | 4-1/8 | 4.125 | 3.988 | 4.763 | 4.546 | 2-3/8 | 2.431 | 2.319 |

Inconel Steel Socket Head Cap Screw Dimensions Chart :

| Nominal Size Of D | Diameter Of Body | Thickness Of Head | Flats Across | Bolts Corners Across | ||||

|---|---|---|---|---|---|---|---|---|

| D (Maximum) | D (Minimum) | H (Maximum) | H (Minimum) | F (Maximum) | F (Minimum) | C (Maximum) | C (Minimum) | |

| m10 | 10.00 | 9.78 | 6.63 | 6.17 | 17.00 | 15.73 | 18.48 | 17.77 |

| m12 | 12.00 | 11.73 | 7.76 | 4.24 | 19.00 | 17.73 | 20.78 | 20.03 |

| m14 | 14.00 | 13.73 | 9.09 | 8.51 | 22.00 | 20.67 | 24.25 | 23.35 |

| m16 | 16.00 | 15.73 | 10.32 | 9.68 | 24.00 | 23.67 | 27.71 | 26.75 |

| m20 | 20.00 | 19.67 | 12.88 | 12.12 | 30.00 | 29.16 | 34.64 | 32.95 |

| m24 | 24.00 | 23.67 | 15.44 | 14.56 | 36.00 | 35.00 | 41.57 | 39.55 |

| m30 | 30.00 | 29.67 | 19.48 | 17.92 | 46.00 | 45.00 | 53.12 | 50.85 |

| m36 | 36.00 | 35.61 | 23.38 | 21.63 | 55.00 | 53.80 | 63.51 | 60.79 |

| m42 | 42.00 | 41.38 | 26.97 | 25.03 | 65.00 | 62.90 | 75.06 | 71.71 |

| m48 | 48.00 | 47.38 | 31.07 | 28.93 | 75.00 | 72.60 | 86.60 | 82.76 |

| m56 | 56.00 | 55.26 | 36.2 | 33.80 | 85.00 | 82.20 | 98.15 | 93.71 |

| m64 | 64.00 | 63.26 | 41.32 | 38.68 | 95.00 | 91.80 | 109.70 | 104.65 |

| m72 | 72.00 | 71.26 | 46.45 | 43.55 | 105.00 | 101.40 | 121.24 | 115.60 |

| m80 | 80.00 | 79.26 | 51.58 | 48.42 | 115.00 | 111.00 | 132.72 | 126.54 |

| m90 | 90.00 | 89.13 | 57.74 | 54.26 | 130.00 | 125.50 | 150.11 | 143.07 |

| m100 | 90.00 | 99.13 | 63.9 | 60.10 | 145.00 | 140.00 | 167.43 | 159.60 |

Inconel Steel Threaded Rod Dimensions Chart :

| D | P |

D

|

P |

|---|---|---|---|

| M2 | 0.4 | M20 | 1.5/2.5 |

| M2.5 | 0.45 | M22 | 1.5/2.5 |

| M3 | 0.5 | M24 | 2/3 |

| M3.5 | 0.6 | M27 | 2/3 |

| M4 | 0.7 | M30 | 2/3.5 |

| M5 | 0.8 | M33 | 2/3.5 |

| M6 | 1 | M36 | 3/4 |

| M8 | 1/1.25 | M39 | 3/4 |

| M10 | 1/1.25/1.5 | M42 | 3/4.5 |

| M12 | 1.25/1.5/1.75 | M45 | 3/4.5 |

| M14 | 1.5/2 | M48 | 3/5 |

| M16 | 1.5/2 | M52 | 3/5 |

| M18 | 1.5/2.5 |

Inconel Steel Flat Washer Dimensions Chart :

| Size Table | USS | SAE | ||||

|---|---|---|---|---|---|---|

| Inside Diameter (I.D.) Of (A) |

Outside Diameter (O.D.) Of (B) |

Thickness Of (C) |

I.D. Of (A) |

O.D. Of (B) |

Thickness Of (C) |

|

| #2 | - | - | - | 3/32" | 1/4" | 0.020" |

| #4 | - | - | - | 1/8" | 5/16" | 0.032" |

| #6 | - | - | - | 5/32" | 3/8" | 0.049" |

| #8 | - | - | - | 3/16" | 7/16" | 0.049" |

Size of Inconel Steel FASTENER :

Inconel Steel Nuts Size Chart :

| Size Of Nut (millimeter) |

Diameter Of (millimeter) |

Height Table (millimeter) |

||

|---|---|---|---|---|

| Hex Nut | Jam Nut | Nylock Nut | ||

| 2 | 4 | 1.6 | 1.2 | - |

| 2.5 | 5 | 2 | 1.6 | - |

| 3 | 5.5 | 2.4 | 1.8 | 4 |

| 4 | 7 | 3.2 | 2.2 | 5 |

| 5 | 8 | 4 | 2.7 | 5 |

| 6 | 10 | 5 | 3.2 | 6 |

| 7 | 11 | 5.5 | 3.5 | - |

| 8 | 13 | 6.5 | 4 | 8 |

| 10 | 17 | 8 | 5 | 10 |

| 12 | 19 | 10 | 6 | 12 |

| 14 | 22 | 11 | 7 | 14 |

| 16 | 24 | 13 | 8 | 16 |

| 18 | 27 | 15 | 9 | 18.5 |

| 20 | 30 | 16 | 10 | 20 |

Inconel Steel Screws Sizes :

| Screw Size | Body Dia | Minimum Thread Length | Hex Key Size | Head Dia | Head Height | Maximum Thread Length |

|---|---|---|---|---|---|---|

| No. 0 | 0.06 | 3/8 | 0.05 | 0.096 | 0.06 | 5/8 |

| No. 1 | 0.073 | 3/8 | 1/16 | 0.118 | 0.073 | 7/8 |

| No. 2 | 0.086 | 1/2 | 5/64 | 0.14 | 0.086 | 7/8 |

| No. 3 | 0.099 | 1/2 | 5/64 | 0.161 | 0.099 | 7/8 |

| No. 4 | 0.112 | 11/16 | 3/32 | 0.183 | 0.112 | 11/8 |

| No. 5 | 0.125 | 11/16 | 3/32 | 0.205 | 0.125 | 1 |

| No. 6 | 0.138 | 11/16 | 7/64 | 0.226 | 0.138 | 11/8 |

| No. 8 | 0.164 | 3/4 | 9/64 | 0.27 | 0.164 | 11/4 |

| No. 10 | 0.19 | 15/16 | 5/32 | 0.312 | 0.19 | 13/8 |

| No. 12 | 0.216 | 15/16 | 5/32 | 0.345 | 0.216 | 11/4 |

| 1/4 | 0.250 | 15/16 | 3/16 | 3/8 | 1/4 | 11/2 |

| 5/16 | 0.3125 | 1-1/16 | 1/4 | 15/32 | 5/16 | 1-3/4 |

| 3/8 | 0.375 | 1-3/16 | 5/16 | 9/16 | 3/8 | 2 |

| 7/16 | 0.438 | 13/16 | 3/8 | 21/32 | 7/16 | 2-1/4 |

| 1/2 | 0.500 | 1-3/8 | 3/8 | 3/4 | 1/2 | 2-1/2 |

| 9/16 | 0.5625 | 1-5/8 | 7/16 | 27/32 | 9/16 | 2-7/16 |

| 5/8 | 0.625 | 1-5/8 | 1/2 | 15/16 | 5/8 | 3 |

| 3/4 | 0.750 | 1-7/8 | 5/8 | 11/8 | 3/4 | 3-1/2 |

| 7/8 | 0.875 | 2-1/16 | 3/4 | 15/16 | 7/8 | 3-3/4 |

| 1 | 1.000 | 2-1/4 | 3/4 | 11/2 | 1 | 4-1/2 |

| 1-1/8 | 1.125 | 2-13/16 | 7/8 | 111/16 | 1-1/8 | 4-21/32 |

| 1-1/4 | 1.250 | 3-1/8 | 7/8 | 17/8 | 1-1/4 | 5-3/32 |

| 1-1/2 | 1.500 | 3-3/4 | 1 | 21/4 | 1-1/2 | 6-5/64 |

| 1-3/4 | 1.750 | 4-3/8 | 11/4 | 25/8 | 1-3/4 | 7-1/8 |

| 2 | 2.000 | 5 | 11/2 | 3 | 2 | 8-7/64 |

Inconel Steel Threaded Rod Size Chart :

|

Size Table Of Threaded Rod

|

per Inch Threads

|

||

|---|---|---|---|

|

Frac. [Number]

|

Decimal

|

UNC

|

UNF

|

|

1/8 [#6]

|

0.1380

|

32

|

40

|

|

5/32 [#8]

|

0.1640

|

32

|

36

|

|

3/16 [#10]

|

0.1900

|

24

|

32

|

|

1/4

|

0.2500

|

20

|

28

|

|

5/16

|

0.3125

|

18

|

24

|

|

3/8

|

0.3750

|

16

|

24

|

|

7/16

|

0.4375

|

14

|

20

|

|

1/2

|

0.5000

|

13

|

20

|

|

9/16

|

0.5625

|

12

|

18

|

|

5/8

|

0.6250

|

11

|

18

|

|

3/4

|

0.7500

|

10

|

16

|

|

7/8

|

0.8750

|

9

|

14

|

|

1

|

1.0000

|

8

|

12, 14

|

|

1 1/8

|

1.1250

|

7

|

12

|

|

1 1/4

|

1.2500

|

7

|

12

|

|

1 3/8

|

1.3750

|

6

|

12

|

|

1 1/2

|

1.5000

|

6

|

12

|

|

1 3/4

|

1.7500

|

5

|

–

|

Inconel Steel Washer Sizes :

| Washer Size | Inner Dia, Basic [in] |

Basic Diameter [in] | Outer Dia, Basic [in] |

Series | Washer Thickness, Basic [in] |

|---|---|---|---|---|---|

| #0 | 0.078 | 0.0600 | 0.188 | - | 0.020 |

| #2 | 0.094 | 0.0860 | 0.250 | - | 0.020 |

| #4 | 0.125 | 0.1120 | 0.312 | - | 0.032 |

| #6 | 0.156 | 0.1380 | 0.375 | - | 0.049 |

| #8 | 0.188 | 0.1640 | 0.438 | - | 0.049 |

| #10 | 0.219 | 0.1900 | 0.500 | - | 0.049 |

| 1/4" | 0.281 | 0.2500 | 0.625 | Narrow | 0.065 |

| 1/4" | 0.312 | 0.2500 | 0.734 | Wide | 0.065 |

| 5/16" | 0.344 | 0.3125 | 0.688 | Narrow | 0.065 |

| 5/16" | 0.375 | 0.3125 | 0.875 | Wide | 0.083 |

| 3/8" | 0.406 | 0.3750 | 0.812 | Narrow | 0.065 |

| 3/8" | 0.438 | 0.3750 | 1.000 | Wide | 0.083 |

| 7/16" | 0.469 | 0.4375 | 0.922 | Narrow | 0.065 |

| 7/16" | 0.500 | 0.4375 | 1.250 | Wide | 0.083 |

| 1/2" | 0.531 | 0.5000 | 1.062 | Narrow | 0.095 |

| 1/2" | 0.562 | 0.5000 | 1.375 | Wide | 0.109 |

| 9/16" | 0.594 | 0.5625 | 1.156 | Narrow | 0.095 |

| 9/16" | 0.625 | 0.5625 | 1.469 | Wide | 0.109 |

| 5/8" | 0.656 | 0.6250 | 1.312 | Narrow | 0.095 |

| 5/8" | 0.688 | 0.6250 | 1.750 | Wide | 0.134 |

| 3/4" | 0.812 | 0.7500 | 1.469 | Narrow | 0.134 |

| 3/4" | 0.812 | 0.7500 | 2.000 | Wide | 0.148 |

| 7/8" | 0.938 | 0.8750 | 1.750 | Narrow | 0.134 |

| 7/8" | 0.938 | 0.8750 | 2.250 | Wide | 0.165 |

| 1" | 1.062 | 1.0000 | 2.000 | Narrow | 0.134 |

| 1" | 1.062 | 1.0000 | 2.500 | Wide | 0.165 |

| 1-1/8" | 1.250 | 1.1250 | 2.250 | Narrow | 0.134 |

| 1-1/8" | 1.250 | 1.1250 | 2.750 | Wide | 0.165 |

| 1-1/4" | 1.375 | 1.2500 | 2.500 | Narrow | 0.165 |

| 1-1/4" | 1.375 | 1.2500 | 3.000 | Wide | 0.165 |

| 1-3/8" | 1.500 | 1.3750 | 2.750 | Narrow | 0.165 |

| 1-3/8" | 1.500 | 1.3750 | 3.250 | Wide | 0.180 |

| 1-1/2" | 1.625 | 1.5000 | 3.000 | Narrow | 0.165 |

| 1-1/2" | 1.625 | 1.5000 | 3.500 | Wide | 0.180 |

| 1-5/8" | 1.750 | 1.6250 | 3.750 | - | 0.180 |

| 1-3/4" | 1.875 | 1.7500 | 4.000 | - | 0.180 |

| 1-7/8" | 2.000 | 1.8750 | 4.250 | - | 0.180 |

| 2" | 2.125 | 2.0000 | 4.500 | - | 0.180 |

Inconel Type Fasteners

Bolts Types :

Nuts Types:

Washer :

Inconel Steel Fasteners Surface Coating :

- Hot Dipped Galvanizing

- Epoxy Coating

- Electro Polished

- Passivation

- Zinc Plating

- Chrome Plating

- Mirror Buffed

- Teflon Coating

- Oxidized

Inconel Steel Price Per Kg (As per demand and manufacturer):

| Price of Inconel Steel Fasteners manufacturer in India | Price in USD (per kg) | Price in Euro (per kg) | Price in UAE Dirham (per kg) |

|---|---|---|---|

| Inconel Steel – 600 Fastener | $3.40 | €2.96 | 77.02 UAE Dirham |

| Inconel Steel 625 Hex Bolts | $4.22 | €3.64 | 8.48 UAE Dirham |

| Inconel Steel Square Nuts – 718 | $4.84 | €4.18 | 26.92 UAE Dirham |

- People also search

- City we Deliver

- Country we export

ASME SA166 industrial Fastener trader in Qatar, Inconel 600 industrial Fastener retailer in Coimbatore, ASME SA166 Hot Forged Fastener retailer in Malaysia, Grade Inconel 601 high tensile Fastener supplier in Oman, ASME SB166 high tensile Fastener stockyards in Malaysia, ASME SB166 high tensile Fastener stockiest in Singapore,UNS N06625 industrial Fastener retailer in Chennai, ASME SB446 industrial Fastener wholesaler in India, UNS N06625 industrial Fastener supplier in Chennai, ASME SB446 Hot Forged Fastener trader in Vietnam, Inconel 718 industrial Fastener retailer in Mumbai, ASTM B637 Hot Forged Fastener stockyards in Pune, Inconel 718 Hot Forged Fastener exporter in Kolkata, Inconel 718 industrial Fastener exporter in Pune, UNS N07718 high tensile Fastener retailer in Singapore, ASTM B637 industrial Fastener exporter in Oman.

ASTM B 166 industrial Fasteners exporter in Pune, Inconel 600 Hot Forged Fasteners supplier in Pune, ASME SB 166 Hot Forged Fasteners dealer in Mumbai, ASTM B 166 Hot Forged Fasteners manufacturer in Bhopal, UNS N06600 industrial Fasteners distributor in Jaipur, ASTM B 166 Hot Forged Fasteners stockiest in Bhopal, ASME SB166 industrial Fasteners wholesaler in Gujarat, Grade Inconel 601 industrial Fasteners manufacturer in Bhubaneswar, ASME SB166 industrial Fasteners exporter in Bhopal, Inconel 601 industrial Fasteners trader in Chennai, Grade Inconel 601 industrial Fasteners manufacturer in Kerala, UNS N06625 high tensile Fasteners stockiest in Coimbatore, Inconel 625 high tensile Fasteners distributor in Gandhinagar, Werkstoff Nr. 2.4856 Hot Forged Fasteners trader in Jamnagar, Werkstoff Nr. 2.4856 industrial Fasteners supplier in Pimpri-Chinchwad, UNS N06625 Hot Forged Fasteners dealer in Jamnagar, ASTM B637 high tensile Fasteners trader in Chennai, UNS N07718 high tensile Fasteners supplier in Vadodara, UNS N07718 high tensile Fasteners stockiest in Bharuch, Inconel 718 high tensile Fasteners dealer in Bengaluru, ASME SB637 high tensile Fasteners dealer in Bengaluru, Inconel 718 industrial Fasteners exporter in Bharuch.

Inconel 600 Hot Forged Fasteners manufacturer in Bahrain, ASME SB 166 high tensile Fasteners manufacturer in Bahrain, ASTM B 166 high tensile Fasteners stockiest in Taiwan, Inconel 600 high tensile Fasteners wholesaler in India, ASTM B 166 Hot Forged Fasteners manufacturer in Jordan, UNS N06600 Hot Forged Fasteners stockiest in India, ASME SB 166 industrial Fasteners manufacturer in Spain, ASME SB166 Hot Forged Fasteners dealer in UK, Grade Inconel 601 Hot Forged Fasteners dealer in Egypt, UNS N06601 industrial Fasteners supplier in Turkey, ASTM B166 high tensile Fasteners manufacturer in Bahrain, ASTM B 166 industrial Fasteners supplier in Thailand, UNS N06625 industrial Fasteners trader in Germany, Inconel 625 Hot Forged Fasteners supplier in Poland, Werkstoff Nr. 2.4856 Hot Forged Fasteners stockiest in Turkey, Inconel 718 Hot Forged Fasteners stockiest in Kuwait, ASTM B637 industrial Fasteners manufacturer in Iran, ASTM B637 high tensile Fasteners exporter in Jordan, ASTM B637 Hot Forged Fasteners wholesaler in Taiwan, ASTM B637 high tensile Fasteners supplier in India, ASME SB637 industrial Fasteners dealer in Saudi Arabia.